1

User Projects & Pictures / Re: Pix of a furnace I want to convert

« on: January 18, 2011, 05:54:57 pm »

Hey DE,

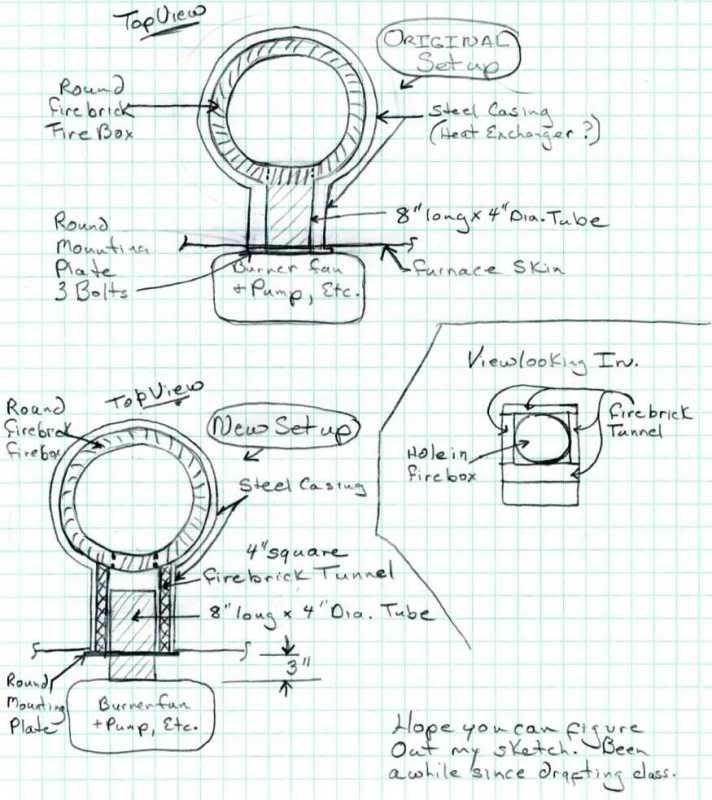

Actually, the fire brick "box" (hut, I guess you are calling it?) is round and conforms to the round"steel casing" in which it is enclosed. (I'm sorry, I don't know all the proper terms and names.) The one photo "kind of" shows it back there, but not a great shot. The fire brick (hut??) is about 1" or so smaller than the steel ____ (tube/casing). It's a very nice looking "hut" with a tapered in lip at the top. I'd like to keep it/use it if possible, since it does just fit in there perfect. So yes, it is all "round".

So what I did was just form a fire brick "tube" back to the opening/access panel. It is square but the flame has to go thru the 4" round hole in the "hut" to get into the chamber. I can open the top of the "tunnel" up if that would be help in the burn. I was thinking the heat coming back around might be a good thing but, they did not have it that way. They had ceramic wool stuffed all around the burner tube, I suppose to protect it. That is why I made a "tunnel" instead of a "trough". I'm just a little concerned about having the burner nozzle 3" back from the actual inside of the "hut". And having to "shoot" thru the round hole in the hut. But that gives me the full 12" to the "target side" of the hut.

I have no problem making/adding a steel box extension, but I'm not sure it would help. (??) Can you help me with that? The access panel that has the burner hole in it, is pretty good size already. It's big enough that I could take the "hut" out, in the 2 pieces in which it was made, if I need to.

I hope that makes things a little easier to understand.

Thanx for putting up with my inexperience and all the help,

Chaz

Actually, the fire brick "box" (hut, I guess you are calling it?) is round and conforms to the round"steel casing" in which it is enclosed. (I'm sorry, I don't know all the proper terms and names.) The one photo "kind of" shows it back there, but not a great shot. The fire brick (hut??) is about 1" or so smaller than the steel ____ (tube/casing). It's a very nice looking "hut" with a tapered in lip at the top. I'd like to keep it/use it if possible, since it does just fit in there perfect. So yes, it is all "round".

So what I did was just form a fire brick "tube" back to the opening/access panel. It is square but the flame has to go thru the 4" round hole in the "hut" to get into the chamber. I can open the top of the "tunnel" up if that would be help in the burn. I was thinking the heat coming back around might be a good thing but, they did not have it that way. They had ceramic wool stuffed all around the burner tube, I suppose to protect it. That is why I made a "tunnel" instead of a "trough". I'm just a little concerned about having the burner nozzle 3" back from the actual inside of the "hut". And having to "shoot" thru the round hole in the hut. But that gives me the full 12" to the "target side" of the hut.

I have no problem making/adding a steel box extension, but I'm not sure it would help. (??) Can you help me with that? The access panel that has the burner hole in it, is pretty good size already. It's big enough that I could take the "hut" out, in the 2 pieces in which it was made, if I need to.

I hope that makes things a little easier to understand.

Thanx for putting up with my inexperience and all the help,

Chaz

I guess it's just time to fire it up and get dirty.

I guess it's just time to fire it up and get dirty.  I just prefer to make at least MOST of my mistakes on paper, (or computer, as it were)

I just prefer to make at least MOST of my mistakes on paper, (or computer, as it were)  . At least that's the way I do the other things I design.

. At least that's the way I do the other things I design.

It's my thinking that the burner is going to actually be "back" further (out the front of the furnace) since I had to increase the distance from the nozzle to the "target". (sorry, I'm not seeing what you're saying) I am basically moving the round mounting plate that goes around the burner tube and mounts to the front wall of the furnace, up 3" towards the nozzle end of that tube. That will give me the 12" that I understand is necessary from the nozzle end to the target. But, I think this may also give undue leverage to the whole burner assembly on that plate, so I was going to make a stand/mount to go under the back, "heavy end" of the burner assembly to help support it. It will be sticking out past the front door of the furnace that covered all that up so I will have to make a "box" and attach (weld) it to the door to cover it up to make it less unsightly.

It's my thinking that the burner is going to actually be "back" further (out the front of the furnace) since I had to increase the distance from the nozzle to the "target". (sorry, I'm not seeing what you're saying) I am basically moving the round mounting plate that goes around the burner tube and mounts to the front wall of the furnace, up 3" towards the nozzle end of that tube. That will give me the 12" that I understand is necessary from the nozzle end to the target. But, I think this may also give undue leverage to the whole burner assembly on that plate, so I was going to make a stand/mount to go under the back, "heavy end" of the burner assembly to help support it. It will be sticking out past the front door of the furnace that covered all that up so I will have to make a "box" and attach (weld) it to the door to cover it up to make it less unsightly.

The CK stuff IS nice but I need to save a buck where I can. Any other suggestions?

The CK stuff IS nice but I need to save a buck where I can. Any other suggestions?